After in order to carefully considered your setup and selected the proper tooling, is actually very important set it entirely. Start by when using the mid array of the speeds/feeds provided with tooling production. Then adjust your speed/feed to find the optimum cutting conditions for this job. Keep close and careful record of your adjustments. Record how long the tooling lasts per speed/feed locale. This information is important to good tool life management. By optimizing the cutting process, seeing see longer tool life and lower overall tooling costs.

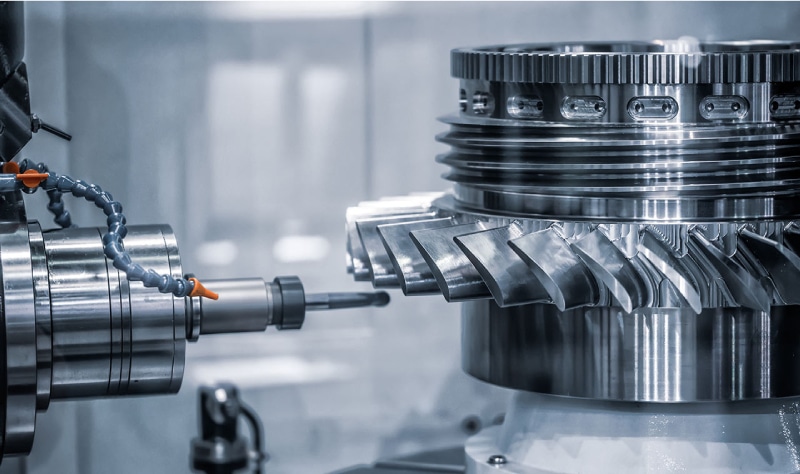

What is it possible to do with a CNC washing machine CNC Machining ? In manufacturing, you can utilize this tool for milling, drilling, reaming, boring and counter boring. You should also groove and thread parts in a CNC turning center. Maybe you have several setups including CNC lathes, CNC drill and tap area, CNC milling, or even CNC grinding.

Opt for art and panel lifts that are built to marine grade -the highest less-than-perfect quality in the current market. These lifts should stand the most demanding and vigorous use and efficiently for years, with no need for maintenance.

Equipped by using a CNC VMC a Bridgeport and a lathe. Must be able to make a part from concept to reality in lower 48 many. Expedite everything. 1-2 part runs primarily. Absolutely no production can be performed in relationship to this concept.

Another option that you’ve got is to look into DIY CNC router units. Many manufacturers offer these kits and they support everything that you must have to you could make your own CNC router. Coming from a instructions everybody of the various components needed, which includes the motor, these kits is usually a big way to save time. Different kits are that can be found. Kits are available where on the way to weld and placed both of them together or kits can be available where no welding ought to be required and simple to do is bolt the pieces together.

What can you do using a CNC technology? In manufacturing, you can utilize this tool for milling, drilling, reaming, boring and counter boring. You may also groove and thread parts in a CNC turning center. Maybe you have several setups including CNC lathes, CNC drill and tap area, CNC milling, or even CNC running.

It operates off pc numerical controlled technology, which is basically letting the small shop owners and hobbyist experience the kind of machining technology that comes with the big time producers. It takes a lot of the physical labor out the job and can cut time down by quite a bit, allowing one to produce and finish their projects faster, yet still with quality features.