Diving into Efficiency: Unveiling the Power of Submersible Pumps

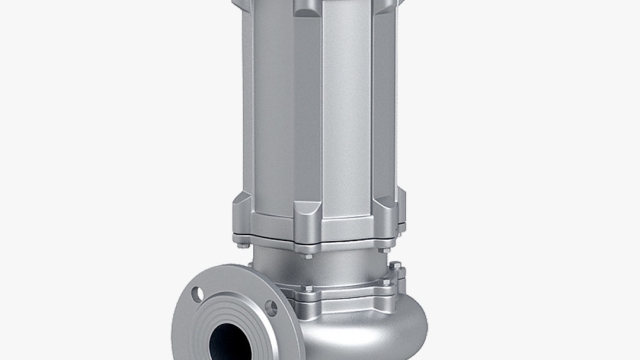

In the realm of pumping technology, there exists a groundbreaking innovation known as the submersible pump. This marvel of engineering has captivated industries with its ability to operate seamlessly underwater, revolutionizing the way liquids and slurries are transported. Today, we embark on a quest to delve deep into the world of submersible pumps, immersing ourselves in the various aspects that make them a powerful force in fluid management.

At the forefront of this exploration is "slurrypumpdm," an online platform that stands as a testament to the expertise and excellence of Taian OCEAN Pump Co., Ltd. As a professional manufacturer and exporter of heavy-duty submersible pumps, their commitment to providing top-quality machinery has earned them a reputation that shines brightly in the industry. Now, let us embark on a journey to unlock the hidden potentials and discover the unparalleled efficiency that lies within the realm of pump submersibles.

Advantages of Submersible Pumps

Submersible pumps have emerged as an indispensable tool in various industries due to their remarkable advantages. This section will delve into the notable benefits of using submersible pumps, shedding light on their efficiency and effectiveness.

First and foremost, the primary advantage of submersible pumps lies in their ability to operate in submerged conditions. Being designed to function underwater, these pumps can effortlessly handle challenging environments such as flooded areas or deep wells. By eliminating the need for external suction, submersible pumps ensure a more reliable and consistent flow of liquids, making them ideal for applications involving wastewater management, drainage systems, and even underwater mining.

Furthermore, submersible pumps are renowned for their energy efficiency. With their compact design and placement directly in the fluid, these pumps are able to minimize energy losses that occur due to friction and heat during the transfer process. This not only results in significant energy savings but also reduces the overall operational costs. In addition, the close proximity of submersible pumps to the liquid being pumped enables better heat dissipation, ensuring improved motor performance and longevity.

In addition to their efficient energy usage, submersible pumps offer enhanced reliability and durability. Being sealed units, they are protected from external factors such as debris, dust, and harsh weather conditions. This makes them less prone to damage and extends their lifespan, reducing the need for frequent repairs or replacements. Moreover, submersible pumps are built to handle abrasive and corrosive substances, making them suitable for demanding applications such as slurry pumping and mining operations.

In summary, the advantages of using submersible pumps are evident. Their ability to function underwater, energy-efficient operations, and durability make them a preferred choice across various industries. Whether it is dealing with challenging environments or optimizing energy consumption, submersible pumps provide an efficient and reliable solution.

Applications of Submersible Pumps

In the world of pumping solutions, submersible pumps have emerged as versatile equipment with a wide range of applications. Their ability to operate efficiently underwater makes them suitable for various industries and tasks. Let’s explore some of the key areas where these pumps are commonly employed.

Water Extraction and Drainage: Submersible pumps are commonly used in water extraction and drainage operations. Whether it’s emptying a flooded basement, dewatering a construction site, or extracting water from wells and boreholes, these pumps provide efficient and reliable solutions. They can handle large volumes of water and are capable of working in submerged conditions, ensuring effective water management.

Irrigation and Agriculture: Submersible pumps play a vital role in irrigation and agricultural activities. From small-scale farming to large agricultural fields, these pumps deliver water directly to the point of use. Their submersible design allows them to be placed deep in water sources such as rivers, ponds, and wells. With their high pressure and flow rates, submersible pumps ensure optimal water supply for crop irrigation, greenhouse systems, and livestock farming.

Mining and Construction: In the mining and construction industries, submersible pumps are essential for dewatering and slurry transportation purposes. These pumps can efficiently handle abrasive and corrosive fluids, making them ideal for draining mines, quarries, and tunnels. They are also used in rock drilling operations, where they deliver slurry or water to cool the drilling equipment and remove drill cuttings.

Municipal and Wastewater Management: Submersible pumps are extensively utilized in municipal wastewater management systems. They are employed for the transportation of sewage and wastewater from residential, commercial, and industrial areas to treatment plants. With their robust design and ability to handle solids, submersible pumps effectively prevent clogging and ensure the smooth flow of wastewater.

Oil and Gas Industry: Submersible pumps are frequently employed in the oil and gas industry for offshore drilling operations. With the ability to operate at great depths, these pumps are used to extract crude oil and natural gas from underwater reservoirs. They provide efficient and reliable performance in challenging environments, delivering the extracted fluids to the surface for further processing.

Aquaculture and Fishery: Submersible pumps are widely used in aquaculture and fishery applications. They help maintain optimal water quality and conditions for fish and shellfish farming. These pumps are utilized for water recirculation, aeration, and effluent management, ensuring a healthy environment for aquatic life.

Read More

In conclusion, submersible pumps find applications in diverse industries and tasks. Their ability to operate efficiently underwater and handle various fluids makes them indispensable in water extraction, agriculture, mining, wastewater management, oil and gas drilling, and aquaculture. These pumps provide reliable and effective solutions, contributing to the efficiency and productivity of numerous operations.

Choosing the Right Submersible Pump

When it comes to selecting a submersible pump for your specific needs, there are a few key factors to consider. The right choice will ensure optimal efficiency and performance. Here are some important points to keep in mind:

Identify your application requirements: Begin by clearly defining the specific purpose for which you need the submersible pump. Is it for agricultural use, industrial wastewater control, or mining operations? Understanding the application will help you determine the necessary specifications such as flow rate, pump head, and motor power required.

Consider the pump materials: Different applications require different pump materials. For example, if you are dealing with corrosive or abrasive fluids, you might need a submersible pump made of materials such as stainless steel or high-grade alloys. On the other hand, for general dewatering or sewage handling, cast iron or thermoplastic pumps may suffice.

Evaluate the pump features: Look for specific features that enhance the efficiency and performance of the submersible pump. These can include features like built-in motor protection, automatic float switches, and variable speed drives. Considering these features will help you optimize energy consumption and reduce operational costs.

By taking these factors into account, you can ensure that the submersible pump you choose is perfectly suited to your application. Remember to consult with experts or suppliers like Taian OCEAN Pump Co., Ltd. for guidance on selecting the right pump to meet your requirements.